Executive Summary

Fort Wayne property owners struggle with recurring mold despite repeated cleaning efforts because conventional approaches fail to identify and correct underlying moisture sources. This comprehensive guide explains why surface treatment proves ineffective, identifies moisture problems specific to Fort Wayne buildings, details health consequences of continued exposure, and describes professional remediation methods that eliminate mold permanently. Property owners will understand the biological reasons mold returns, recognize signs of hidden moisture problems, learn what distinguishes professional remediation from DIY attempts, and discover prevention strategies maintaining mold-free conditions long-term.

When Persistence Meets Reality: Jennifer’s Commercial Property Nightmare

Jennifer Kowalski owned a small commercial building in downtown Fort Wayne housing her dental practice on the first floor and rental office space on the second floor. Three years ago, her receptionist noticed small black spots appearing on the wall behind the reception desk.

Jennifer immediately called her maintenance contractor who cleaned the area thoroughly and repainted. The work looked perfect. Two months later, the mold returned in the same location, slightly larger. Another cleaning and repainting. Six weeks later, it appeared again, now spreading to adjacent walls.

This pattern continued for 18 months. Jennifer spent over $3,000 on repeated cleaning, painting, and various antimicrobial treatments. Worse, her second-floor tenant developed respiratory problems and cited the ongoing mold issue when terminating their lease early. The vacancy cost Jennifer $18,000 in lost rent over the following year as prospective tenants expressed concerns about visible mold problems.

Jennifer finally contacted certified remediation specialists after her fourth coating of special “mold-blocking” paint failed within three months. The professional investigation revealed a roof membrane failure allowing water infiltration during certain wind-driven rain conditions. The moisture had been entering the wall cavity for years, creating perfect conditions for extensive mold growth inside walls throughout both floors.

Professional remediation required removing affected drywall, treating structural members, repairing the roof membrane, improving interior ventilation, and replacing damaged materials. The project cost $14,000 but delivered permanent resolution. Three years later, Jennifer’s building remains mold-free. She quickly secured a new tenant at higher rent than the previous tenant. The improved indoor air quality and professional documentation of proper remediation made her property more attractive to prospective tenants.

Jennifer’s total DIY expenses, lost rent, and final professional remediation cost substantially more than addressing the problem professionally at first discovery would have. Her experience illustrates how seemingly economical DIY approaches often prove more expensive long-term.

Why Do DIY Mold Cleaning Methods Keep Failing?

Homeowners and property managers who clean mold repeatedly experience frustration because their approach addresses symptoms rather than root causes. Understanding why requires understanding mold biology.

The Biology Behind Mold Recurrence

Mold exists in two forms: the visible surface growth you see and the invisible subsurface network you don’t. When mold establishes on a surface, it immediately begins developing hyphae, which are microscopic root-like structures.

These hyphae serve several functions:

- Nutrient absorption: Extract nutrients from materials the mold grows on

- Water acquisition: Pull moisture from building materials or air

- Structural support: Anchor the colony firmly to surfaces

- Growth and spread: Extend throughout porous materials establishing new growth points

Individual hyphae measure only 2 to 10 microns in diameter, approximately 1/10th the width of a human hair. They remain completely invisible without microscopy. These structures penetrate several inches into porous materials like drywall, wood, insulation, and ceiling tiles.

When you clean visible mold using spray cleaners, bleach, or other household products, you remove only surface growth. The hyphae network remains alive and active inside the material. Within days or weeks, these surviving roots produce new visible growth. You haven’t failed at cleaning; you’ve simply fought the wrong battle.

Additionally, commercial properties face unique challenges. High occupancy generates moisture through breathing, activities, and equipment operation. Business operations may produce additional moisture through cooking, manufacturing, or service provision. These factors create more favorable conditions for mold growth than typical residential environments.

Why Bleach Fails on Porous Materials

Bleach remains the most commonly used DIY mold treatment despite being ineffective on porous surfaces. The EPA, CDC, and professional remediation organizations all state that bleach cannot adequately treat mold on porous materials.

Bleach solution consists primarily of water with approximately 5 to 8 percent sodium hypochlorite (the active cleaning agent). When applied to porous materials:

- Water component penetrates into the material

- Sodium hypochlorite component (which kills mold) cannot penetrate due to molecular size

- Water feeds subsurface hyphae while surface chlorine evaporates

- Temporary cosmetic improvement occurs while underlying problem worsens

Bleach works exclusively on non-porous surfaces like glass, tile, metal, and sealed concrete. Even on these surfaces, it provides only temporary protection without residual effectiveness.

The Moisture Equation Nobody Addresses

Every mold problem has an active moisture source. This fundamental truth bears repeating: mold cannot grow without moisture exceeding approximately 60 percent relative humidity or 16 percent material moisture content. Finding and eliminating moisture sources matters exponentially more than removing visible mold.

Common moisture sources in Fort Wayne properties include:

- Roof leaks: From aging materials, storm damage, or installation defects

- Plumbing failures: Slow leaks inside walls or under floors

- Foundation infiltration: From hydrostatic pressure or poor drainage

- Condensation: From temperature differentials between interior and exterior

- Poor ventilation: Allowing humidity accumulation in bathrooms, kitchens, or mechanical spaces

- HVAC issues: From condensate drain clogs, ductwork problems, or oversized equipment

- Ground moisture: Rising through concrete slabs or crawl spaces

Property owners who clean mold without addressing moisture sources guarantee recurrence. The timeline varies based on moisture level and temperature, but recurrence is mathematically certain.

Jennifer’s roof membrane allowed water infiltration only during wind-driven rain from specific directions. This explained why simple roof inspections during dry weather revealed nothing. The intermittent nature made identification difficult, but the moisture provided sufficient resources for continuous mold growth regardless of cleaning frequency.

What Fort Wayne Climate and Construction Factors Contribute to Recurring Mold?

Fort Wayne faces specific environmental conditions and building characteristics creating vulnerability to mold problems.

Regional Climate Patterns

Northeast Indiana experiences humid continental climate with pronounced seasonal variations:

Summer humidity: June through August regularly reaches 70 to 80 percent relative humidity. Dew points in the 65 to 75 degree range create muggy conditions where moisture condenses readily on cool surfaces.

Winter temperature stress: January average lows near 16 degrees Fahrenheit create significant temperature differentials between heated interiors and cold exteriors. These differentials cause condensation when interior moisture contacts cold surfaces.

Freeze-thaw cycles: Fort Wayne experiences numerous freeze-thaw transitions throughout winter. These cycles stress building materials, create expansion and contraction, and open pathways for water intrusion.

Precipitation patterns: Fort Wayne averages 36 inches of annual precipitation distributed fairly evenly across months. This consistent moisture availability keeps outdoor humidity elevated and increases infiltration opportunities.

Snow load and ice dams: Average winter snowfall of 33 inches creates ice dam potential. These dams trap water on roofs, forcing it under shingles and into building cavities.

Historic Building Vulnerabilities

Fort Wayne contains numerous buildings constructed between 1900 and 1970. These structures present specific characteristics favoring mold growth:

Brick construction: Common in commercial downtown buildings, brick absorbs and transmits moisture from exterior to interior. Without proper vapor barriers (often absent in historic construction), this moisture enters occupied spaces.

Minimal insulation: Many older buildings lack adequate insulation in walls, ceilings, or foundations. This deficiency creates cold surface temperatures promoting condensation.

Single-pane windows: Original windows allow significant condensation during cold weather. Moisture runs down windows onto sills, walls, and floors.

Natural ventilation design: Buildings designed before mechanical ventilation relied on operable windows and natural air currents. Modern occupancy and air conditioning systems eliminate this air exchange while increasing moisture generation.

Aging building systems: Plumbing, roofing, and mechanical systems in older buildings approach or exceed service life, increasing failure probability.

Modern Construction Challenges

Conversely, newer Fort Wayne buildings sometimes create mold problems through contemporary construction methods:

Tight building envelopes: Energy efficiency measures reduce air exchange, potentially trapping moisture inside without adequate mechanical ventilation.

Complex HVAC systems: Modern heating, cooling, and ventilation equipment has more components and more potential failure points. Oversized systems short-cycle without proper dehumidification.

Incorrect vapor barrier installation: Moisture control requires vapor barriers on warm sides of insulation. Incorrect placement traps rather than excludes moisture.

Thermal bridging: Steel studs or poorly designed envelope assemblies create cold spots where condensation occurs.

Commercial Property Specific Issues

Commercial buildings face unique moisture challenges:

High occupancy loads: More people generate more moisture through breathing, activities, and use of facilities.

Process moisture: Restaurants, salons, medical facilities, and manufacturing operations generate substantial moisture through business activities.

24/7 operation: Continuous operation provides no recovery time for buildings to dry between occupancy periods.

Deferred maintenance: Commercial property owners sometimes delay maintenance due to cost concerns, allowing minor problems to become major issues.

Tenant improvements: Modifications by various tenants over time may inadvertently create moisture problems through changes to drainage, ventilation, or building envelope.

What Hidden Moisture Sources Sustain Mold Growth Despite Repeated Cleaning?

Professional mold investigation focuses intensively on moisture source identification because correction determines remediation success.

Roof System Failures

Commercial and residential roof systems develop multiple vulnerability points:

Membrane deterioration: Flat or low-slope roofs common on commercial buildings use membrane roofing (EPDM, TPO, or modified bitumen). These materials have 15 to 30 year service lives. Aging causes brittleness, shrinkage, and cracking. UV exposure degrades materials even before listed service life.

Flashing failures: Transitions between roof surfaces and walls, parapets, equipment penetrations, and drainage components require proper flashing. Original installation defects, aging sealants, or physical damage create water entry points.

Ponding water: Inadequate drainage slope causes water accumulation in low spots. While roofing materials are designed to be waterproof, constant water exposure accelerates deterioration.

Ice dam formation: Fort Wayne winter conditions create ice dams on both sloped and flat roofs. These dams trap water, forcing it under roofing materials and into building cavities.

Mechanical equipment condensate: Rooftop HVAC units generate condensation requiring proper drainage. Clogged or disconnected drain lines release water on roof surfaces, saturating insulation and entering building interiors.

Jennifer’s roof membrane had developed multiple small cracks around a rooftop HVAC unit. The cracks remained difficult to identify during visual inspection but allowed significant water entry during specific wind-driven rain conditions.

Plumbing System Vulnerabilities

Building plumbing systems, especially in older properties, present numerous failure opportunities:

Supply line failures: Copper pipes develop pinhole leaks from corrosion, particularly in aggressive water conditions. Galvanized pipes corrode internally, restricting flow and developing leaks. Modern PEX connections can fail from improper installation or stress.

Drain line problems: Cast iron drain pipes common in older buildings corrode through, creating leaks. PVC joints can separate from building movement or improper installation.

Fixture leaks: Toilets, sinks, and other fixtures develop slow leaks at connections, wax rings, or supply lines. These leaks may be too small to notice but provide adequate moisture for mold growth.

Water heater issues: Aging water heaters develop tank corrosion, valve leaks, or connection problems. Water released gradually over time saturates surrounding materials.

Hidden leaks: The most problematic leaks occur inside walls, above ceilings, or under floors where they remain invisible until significant damage develops.

Foundation and Below-Grade Moisture

Buildings with basements, crawl spaces, or below-grade spaces face constant moisture pressure:

Hydrostatic pressure: Groundwater creates pressure against foundation walls and floors. This pressure forces moisture through concrete pores, cracks, and construction joints.

Poor exterior drainage: Inadequate lot grading, missing or clogged gutters, or insufficient downspout extensions direct water toward rather than away from foundations.

Foundation cracks: Concrete foundations crack from settling, freeze-thaw cycles, or structural stress. These cracks provide pathways for water entry.

Sump pump failures: Properties relying on sump pumps face flooding risk when pumps fail, power outages occur, or discharge systems freeze.

Capillary action: Moisture wicks upward from ground through concrete and masonry materials, entering floor assemblies and lower walls.

Moisture from below-grade spaces migrates upward through the stack effect. As warm air rises in buildings, it creates negative pressure at lower levels. This negative pressure pulls humid air from basements and crawl spaces upward through floor penetrations, utility chases, and wall cavities. The moisture enters upper floors and creates mold growth in surprising locations far from the actual source.

HVAC System Moisture Problems

Heating, ventilation, and air conditioning systems manage indoor climate but sometimes create moisture issues:

Condensate drain problems: Air conditioning generates substantial condensation requiring proper drainage. Drain line clogs from algae growth, debris, or installation defects cause water overflow into air handler cabinets, ductwork, or building cavities.

Ductwork condensation: Inadequately insulated or sealed ductwork running through unconditioned spaces sweats during cooling operation. This condensation drips into ceiling cavities or wall spaces.

Air handler leaks: Cabinet seams, access panels, or filter frames develop gaps allowing conditioned air to escape. This air contacts different temperature surfaces causing condensation.

Oversized equipment: HVAC systems sized too large for spaces cool quickly without adequate dehumidification. Properties maintain comfortable temperatures but retain excessive humidity supporting mold growth.

Poor maintenance: Dirty coils, clogged filters, and neglected drain pans create conditions favoring moisture accumulation and mold growth within systems. This contamination then spreads spores throughout buildings.

Condensation From Temperature Differentials

Fort Wayne’s climate creates multiple condensation scenarios:

Cold surface condensation: Warm, humid interior air contacts cold exterior walls, windows, or ceiling areas creating condensation. This commonly affects north-facing walls receiving minimal solar heating.

Summer condensation: Cool interior surfaces from air conditioning become condensation points when humid outdoor air infiltrates through leaks or during door operation.

Thermal bridging: Metal structural members, window frames, or poorly insulated areas create cold spots where condensation concentrates.

Attic condensation: Warm, humid air from living spaces enters attics through gaps and penetrations. This moisture condenses on cold roof decking during winter or hot attic surfaces during summer.

These condensation patterns operate invisibly until mold reveals their presence. Properties might have active condensation for months or years before visible problems develop.

How Does Continued Mold Exposure Affect Health in Commercial and Residential Settings?

Recurring mold exposure presents greater health risks than single incidents because immune sensitization increases with repeated contact.

Respiratory System Effects

Mold spores sized 3 to 40 microns penetrate deep into lung tissue. Repeated inhalation causes progressively severe effects:

Asthma development and aggravation: People without previous asthma may develop it following repeated exposure. Those with existing asthma experience increased attack frequency, severity, and medication requirements. Children face particularly high risk as their respiratory systems continue developing.

Chronic obstructive pulmonary disease: Long-term exposure contributes to COPD development or progression. Symptoms include persistent cough, breathing difficulty, and reduced lung function.

Allergic bronchopulmonary aspergillosis: Serious fungal lung infection occurring when Aspergillus mold causes severe allergic reaction. This condition requires aggressive medical treatment and can cause permanent lung damage.

Hypersensitivity pneumonitis: Immune system overreaction to mold exposure causing lung inflammation. Symptoms mimic pneumonia but persist until exposure stops and may require corticosteroid treatment.

Immune System Sensitization

Each mold exposure trains immune systems to react more strongly:

Initial tolerance: First exposures may produce minimal symptoms in healthy individuals.

Progressive reaction: Subsequent exposures trigger increasingly strong responses as immune systems become sensitized.

Permanent sensitivity: Advanced sensitization can become permanent, meaning even minute spore quantities cause significant reactions throughout life.

Cross-reactivity: Sensitization to one mold species may cause reactions to related species, expanding the range of problematic exposures.

Neurological and Cognitive Impacts

Certain mold species produce mycotoxins affecting nervous systems:

Cognitive impairment: Memory problems, concentration difficulty, and mental fog affect work performance and daily activities.

Mood disorders: Anxiety, depression, and irritability may result from mycotoxin exposure or develop secondary to chronic illness.

Chronic fatigue: Persistent exhaustion unrelieved by rest affects quality of life and productivity.

Neurological symptoms: Headaches, dizziness, balance problems, and peripheral neuropathy can occur with certain mycotoxin exposures.

Commercial Property Liability Concerns

Property owners face additional considerations:

Tenant health claims: Tenants experiencing health problems from mold exposure may pursue legal action against property owners.

Employee concerns: Businesses with mold problems risk employee complaints, workers compensation claims, or regulatory citations from health departments or OSHA.

Liability insurance: Mold problems may affect insurance coverage or future premiums.

Business disruption: Health problems among staff reduce productivity and may require business closure during remediation.

Reputation damage: Visible mold problems or tenant complaints damage property reputation, affecting leasing and property values.

Jennifer’s tenant developed chronic respiratory problems during their tenancy. While they didn’t pursue legal action, their lease termination and subsequent difficulty finding replacement tenants cost Jennifer substantially more than proper initial remediation would have.

What Professional Approaches Stop Mold Permanently Where DIY Methods Fail?

Professional mold remediation succeeds through comprehensive methodology addressing root causes rather than just visible symptoms.

Comprehensive Moisture Investigation

Professional remediation begins with thorough moisture assessment using specialized equipment:

Infrared thermal imaging: Detects temperature patterns indicating moisture presence. Wet materials appear cooler than surrounding dry materials because moisture affects thermal properties. Thermal imaging reveals moisture inside walls, above ceilings, and in other hidden locations without destructive exploration.

Moisture meter surveys: Electronic moisture meters provide precise measurements of moisture content in various building materials. Different materials have different acceptable moisture levels. Wood framing should be below 16 percent. Drywall should be below 13 percent. Concrete varies based on type and application. Professionals know these standards and identify materials requiring attention.

Relative humidity mapping: Hygrometers measure relative humidity throughout properties. This data reveals moisture patterns, identifies problematic areas, and helps determine appropriate remediation strategies.

Inspection cameras: Borescopes and inspection cameras allow visual examination inside wall cavities, above ceilings, and in other concealed spaces. Small access holes accommodate cameras without requiring extensive demolition.

Building pressure testing: Blower door tests measure building air tightness and identify infiltration points where humid outdoor air enters.

This investigation typically reveals multiple moisture sources. The visible mold growth indicates just one problem location while others remain hidden. Comprehensive investigation finds all issues requiring correction.

Complete Source Correction Before Remediation

Professional protocols require eliminating water intrusion before beginning mold removal. Active moisture sources guarantee treatment failure regardless of removal thoroughness or product quality.

Corrections vary based on specific situations but commonly include:

Roofing repairs: From simple flashing replacement or sealant application to complete roof system replacement depending on condition and remaining service life.

Plumbing corrections: Including pipe replacement, fixture repairs, water heater replacement, or complete system updates.

Foundation waterproofing: Exterior drainage improvements, interior drainage systems, sump pump installation or replacement, crack injection, or vapor barrier installation.

Ventilation upgrades: New or improved exhaust fans in bathrooms and kitchens, attic ventilation enhancement, or mechanical ventilation systems for whole buildings.

HVAC modifications: System replacement if oversized, improved condensate drainage, ductwork repairs or replacement, or control system updates providing better humidity management.

Building envelope improvements: Window replacement, wall insulation upgrades, air sealing, or vapor barrier installation addressing condensation problems.

Drainage corrections: Lot regrading, gutter installation or repair, downspout extensions, or surface drainage channels.

These corrections address fundamental problems making mold growth possible. Remediating mold without source correction wastes resources and absolutely guarantees recurrence within weeks or months.

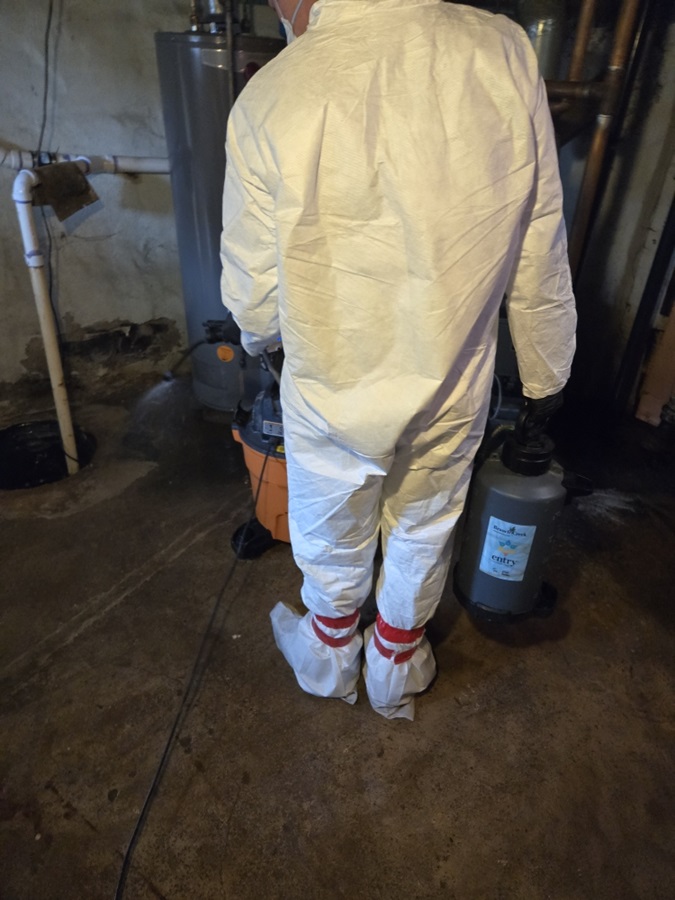

Proper Containment and Protection Protocols

Professional containment prevents mold spread during remediation activities. Disturbing colonies releases astronomical spore quantities into air. Without containment, these spores contaminate previously unaffected areas throughout properties.

Professional containment includes:

Physical barriers: Heavy-gauge polyethylene sheeting creates sealed work area boundaries. All penetrations receive careful sealing with specialized tapes or spray foam.

Negative air pressure: HEPA-filtered air scrubbers exhaust air from contained work areas. This creates negative pressure preventing contaminated air from escaping even if small gaps exist in barriers.

Controlled entry and exit: Designated access points include decontamination procedures. Workers pass through transition areas where HEPA vacuuming removes spores before exiting.

Critical barriers: Large or sensitive projects require two-layer containment with separate work areas and decontamination chambers preventing any cross-contamination.

Personal protective equipment: Workers wear appropriate respiratory protection (minimum N-95, often full-face respirators), disposable coveralls, gloves, and shoe covers.

These protocols seem extensive but prove essential for preventing spore spread. A single disturbed mold colony can release billions of spores contaminating entire properties if remediation occurs without proper containment.

Removal of Contaminated Porous Materials

Professional standards developed by the Institute of Inspection, Cleaning and Restoration Certification (IICRC) require removing porous materials with significant mold contamination:

Drywall: Visible mold growth on drywall indicates deep hyphae penetration requiring removal. Remediation cuts drywall at least 12 inches beyond visible contamination, often removing entire sheets ensuring complete elimination.

Insulation: Any mold presence in insulation requires complete removal. Insulation cannot be effectively cleaned. Compressed or disturbed insulation loses thermal efficiency even if cleaning were possible.

Ceiling tiles: Porous acoustical ceiling tiles cannot be effectively cleaned when contaminated.

Carpeting: Mold penetration into carpet and padding requires removal of both materials.

Wood materials: Surface mold on structural wood can be treated if caught early. Deep penetration requires replacement of affected members. Manufactured wood products (particle board, MDF, OSB) require removal when contaminated as they cannot be effectively treated.

This removal seems drastic and expensive to property owners hoping to minimize costs. However, attempting to save heavily contaminated porous materials absolutely guarantees recurrence. The hyphae penetration proves too deep for any surface treatment effectiveness regardless of product or methodology.

Non-porous materials including metal studs, concrete, properly sealed wood, glass, and ceramic tile can typically be cleaned and treated rather than replaced.

Jennifer’s commercial building required removing substantial drywall on both floors. The expense frustrated her initially, but the investment delivered permanent resolution. Attempting to treat without removal would have wasted money and guaranteed continued problems.

Industrial Air Filtration During and After Work

Professional air scrubbers differ dramatically from consumer air purifiers:

- Processing capacity: Commercial scrubbers process 400 to 2,000 cubic feet per minute compared to 100 to 250 for consumer units

- Filtration efficiency: HEPA filters capture 99.97 percent of particles 0.3 microns and larger, removing nearly all mold spores from air

- Negative pressure capability: Industrial units create negative pressure essential for proper containment

- Continuous operation: Run throughout projects and 24 to 48 hours after completion

- Pre-filtration: Include multi-stage filtration protecting expensive HEPA filters and extending service life

- Monitoring systems: Built-in manometers and airflow indicators confirm proper operation

These machines cycle entire work area volumes multiple times hourly, capturing spores released during demolition, cleaning, and reconstruction activities. This protection proves impossible with consumer equipment.

EPA-Registered Professional Antimicrobial Products

Professional antimicrobial treatments differ fundamentally from consumer products:

- Specific formulation: Designed and tested specifically for mold remediation rather than general cleaning

- EPA registration: Undergo rigorous testing and registration for specific uses

- Penetration capability: Formulated to penetrate porous materials reaching subsurface hyphae

- Residual protection: Provide ongoing protection for weeks or months after application

- Species effectiveness: Tested against specific mold species confirming effectiveness

- Safety profiles: Meet standards for indoor use with proper ventilation and application procedures

Professionals select products based on specific situation requirements. Different antimicrobials serve different purposes including killing active growth, preventing regrowth, encapsulating surfaces where complete removal proves impractical, or treating HVAC systems.

Post-Remediation Verification Testing

Professional remediation includes verification confirming successful completion:

Clearance air sampling: Independent laboratories analyze air samples collected after remediation completion. Spore counts and species identification confirm levels returned to normal ranges (equal to or lower than outdoor control samples collected simultaneously).

Surface sampling: In some situations, surface sampling confirms no viable mold remains on treated materials.

Visual inspection: Certified inspectors examine all treated areas confirming no visible mold remains and all work completed to professional standards.

Moisture verification: Final moisture readings throughout treated areas confirm all materials dried to acceptable levels and moisture sources corrected.

Comprehensive documentation: Complete reports detail all work performed, products used, test results, and extensive photographic documentation. This documentation serves multiple purposes: insurance claims, future property sales, health investigations if symptoms persist, or legal protection against future claims.

This verification provides objective confirmation that subjective judgment and visual inspection cannot match. Property owners receive documented proof of successful remediation rather than just assurance.

When Should Fort Wayne Property Owners Call Professional Remediation Specialists?

Certain situations require professional intervention from the beginning:

Large Contaminated Areas

EPA guidelines recommend professional remediation when visible mold exceeds 10 square feet (approximately 3 feet by 3 feet or a single large patch). Large colonies require containment, safety protocols, and removal procedures beyond typical owner capabilities.

DIY attempts on large areas risk:

- Massive spore release contaminating unaffected spaces

- Inadequate protective equipment exposing workers to dangerous levels

- Incomplete removal guaranteeing recurrence and wasted effort

- Failure to identify and address additional hidden contamination

Recurring Growth After Multiple Cleaning Attempts

Mold returning after two or three cleaning attempts demonstrates DIY methods cannot solve the problem. Continuing the same approach wastes money while problems worsen.

Professional assessment identifies factors preventing DIY success: moisture sources requiring specialized repair, contamination in hidden locations, or mold species requiring specific treatments.

Jennifer’s 18 months of repeated attempts cost more than professional remediation would have initially. Each failed attempt wasted money while moisture continued causing progressive damage. Professional intervention at first recurrence would have saved thousands.

HVAC System Contamination

Mold growth in mechanical equipment spreads spores throughout properties every time systems operate. This contamination:

- Requires specialized cleaning equipment and procedures

- Risks permanent equipment damage if performed incorrectly

- Involves components difficult or impossible to access without proper tools and training

- May indicate moisture problems requiring system modifications or replacement

Professional HVAC remediation includes complete ductwork cleaning, coil treatment, air handler decontamination, drain system clearing, and system modifications preventing recurrence.

Commercial Properties With Occupants or Tenants

Commercial property mold problems require professional handling due to:

- Liability concerns: Occupant health problems create potential legal exposure

- Regulatory compliance: Health departments or OSHA may require professional remediation

- Documentation requirements: Insurance or legal situations require professional documentation

- Business continuity: Professional teams work efficiently minimizing business disruption

- Occupant safety: Proper containment protects occupants from exposure during work

Attempting DIY remediation in occupied commercial buildings risks health, safety, legal, and business consequences far exceeding professional remediation costs.

Health Symptoms in Occupants

When building occupants experience respiratory problems, allergic reactions, asthma attacks, chronic sinus infections, or other symptoms potentially connected to mold exposure, professional remediation becomes a health necessity.

Continued exposure while attempting DIY solutions risks:

- Progressive immune sensitization increasing reaction severity

- Permanent respiratory damage from certain exposures

- Chronic health conditions requiring ongoing medical care

- Effects on developing systems in children

Professional remediation quickly eliminates exposure risks protecting occupant health.

Pre-Purchase, Pre-Sale, or Property Transfer Situations

Real estate transactions involving properties with mold history or current problems require professional intervention:

Buyers: Professional assessment before purchase reveals full problem extent and required repairs. This information supports negotiation, purchase decisions, or contract contingencies. Without professional assessment, buyers risk inheriting expensive problems and ongoing health concerns.

Sellers: Professional remediation with documentation demonstrates proper problem resolution. This disclosure satisfies legal obligations, supports asking price, prevents future liability, and facilitates transactions.

Property managers: Professional handling protects owners from liability while documenting proper response to tenant concerns.

Transactions involving mold without professional remediation frequently result in disputes, contract failures, or litigation costing dramatically more than remediation.

How Does Professional Remediation Cost Compare to Cumulative DIY Expenses?

Many property owners delay professional remediation due to cost concerns. However, complete analysis often reveals professional intervention costs less than cumulative DIY attempts plus associated consequences.

Documented DIY Expenses

Each DIY cleaning attempt requires:

- Cleaning products and antimicrobials: $25 to $75

- Protective equipment (respirators, gloves, coveralls, eye protection): $30 to $100

- Repainting materials: $50 to $200

- Equipment rental (dehumidifiers, fans, air scrubbers): $50 to $300

- Replacement HVAC filters contaminated during cleaning: $20 to $60

Jennifer spent approximately $250 per attempt across 8 major cleaning efforts over 18 months, totaling $2,000. Additional expenses included special “mold-killing” paint costing $120 per gallon (she used 6 gallons total), dehumidifier purchases ($450 for two units), and various other products marketed for mold treatment.

Her total DIY expenses exceeded $3,000 without solving the problem.

Hidden Costs Often Overlooked

Lost productivity: Time spent researching, purchasing materials, performing cleaning, and repainting has real value. Jennifer personally invested approximately 100 hours in her remediation attempts.

Property damage escalation: Untreated moisture sources cause progressive damage. Jennifer’s initial small ceiling stain expanded into structural damage requiring extensive repairs. Her final professional remediation cost more than it would have initially because the problem spread.

Tenant issues: Jennifer’s tenant terminated their lease early citing ongoing mold problems. The resulting vacancy cost $18,000 in lost rent. Additionally, visible mold problems deterred prospective tenants, extending vacancy periods.

Property value impact: Properties with documented mold history suffer decreased value. Professional remediation with proper documentation minimizes this impact.

Insurance implications: Some insurance policies exclude future mold claims if previous problems weren’t professionally addressed. DIY remediation can create coverage gaps.

Professional Remediation Investment

Fort Wayne area professional mold remediation typically costs:

- Small residential projects (under 10 square feet): $700 to $2,500

- Medium residential projects (10 to 100 square feet or single room): $2,500 to $7,000

- Large residential projects (multiple rooms or over 100 square feet): $7,000 to $25,000

- Small commercial projects: $2,000 to $8,000

- Medium commercial projects: $8,000 to $30,000

- Large commercial projects: $30,000 to $100,000+

Pricing factors include:

- Contamination extent and severity

- Number and complexity of moisture sources

- Structural damage requiring correction

- Amount of material requiring removal and replacement

- Access difficulty and working conditions

- Required reconstruction and finishing

- Business disruption considerations for commercial properties

Professional remediation includes:

- Permanent problem resolution with warranties

- Prevention strategy implementation stopping recurrence

- Professional documentation supporting insurance, legal, or transaction needs

- Health protection for occupants

- Peace of mind ending frustration and uncertainty

Jennifer’s professional remediation cost $14,000. Combined with her failed DIY attempts and lost rent, her total expenses exceeded $35,000. Professional intervention at first discovery would have cost approximately $6,000 to $8,000, saving her more than $27,000 while avoiding 18 months of frustration and health concerns.

What Prevention Strategies Maintain Mold-Free Conditions After Professional Remediation?

Professional remediation solves existing problems. Long-term success requires ongoing prevention:

Humidity Control Systems

Maintaining indoor relative humidity between 30 and 50 percent prevents mold growth:

Whole-building dehumidifiers: Large properties benefit from commercial-grade systems integrated with HVAC or operating independently. These units:

- Remove 100+ pints moisture daily

- Include automatic controls maintaining setpoint humidity

- Drain condensate to plumbing systems or through dedicated lines

- Operate efficiently across wide temperature ranges

Portable dehumidifiers: Target specific problem areas. Select units with capacity appropriate for space size (typically 50 to 70 pints daily for basements or storage areas).

Humidistats: Monitor humidity continuously, activating dehumidification equipment automatically when levels exceed thresholds.

Strategic Ventilation Improvements

Moisture removal requires adequate ventilation:

Bathroom ventilation: Minimum 50 CFM exhaust capacity for standard bathrooms, 100+ CFM for larger spaces. Fans should:

- Exhaust outdoors (never into attics or crawl spaces)

- Include humidity sensors or timers ensuring adequate run time

- Receive regular cleaning maintaining airflow capacity

Kitchen exhaust: Range hoods exhausting outdoors rather than recirculating. Minimum 100 CFM for standard cooking, 400+ CFM for commercial-style cooking.

Mechanical ventilation: Tight modern buildings require mechanical ventilation replacing natural air exchange. Energy recovery or heat recovery ventilators provide fresh air while minimizing energy loss.

Attic ventilation: Balanced soffit and ridge or gable ventilation prevents moisture accumulation. Modern building codes require approximately 1 square foot of ventilation per 150 square feet of attic floor.

Regular Professional Maintenance and Inspections

Annual inspections identify problems before they escalate:

- Comprehensive moisture assessment using professional equipment

- Thermal imaging identifying hidden moisture

- Visual inspection of historical problem areas

- HVAC system evaluation including ductwork and drainage

- Plumbing system assessment

- Roof and building envelope inspection

- Foundation and below-grade space examination

These inspections typically cost $300 to $600 for residential properties, $600 to $1,500 for commercial properties depending on size. The investment prevents problems costing thousands to address.

Building Maintenance Best Practices

Regular maintenance prevents many moisture problems:

- Gutter maintenance: Clean twice yearly preventing overflow

- Downspout management: Extend at least 6 feet from foundations

- Landscaping grades: Maintain slopes directing water away from buildings

- Roof inspections: Annual inspections identifying problems early

- Plumbing checks: Regular inspection of accessible plumbing, immediate repair of any leaks

- HVAC maintenance: Professional service annually including condensate drain cleaning

- Filter changes: Monthly or quarterly depending on filter type

- Seal maintenance: Annual inspection and repair of caulking around windows, doors, and penetrations

Operational Procedures

Daily operations significantly impact moisture levels:

- Use exhaust fans during and after moisture-generating activities

- Address spills and leaks immediately

- Maintain consistent indoor temperatures preventing condensation

- Monitor indoor humidity keeping levels below 60 percent

- Ensure adequate air circulation around storage items and against exterior walls

- Report concerns promptly rather than allowing problems to develop

Commercial properties benefit from training staff or tenants on moisture awareness and reporting procedures.

Why Choose PuroClean Disaster Restoration of West Fort Wayne?

PuroClean Disaster Restoration of West Fort Wayne provides Fort Wayne property owners with certified expertise, advanced technology, and comprehensive solutions for mold problems. Our approach delivers permanent resolution rather than temporary cosmetic improvement.

Our team includes IICRC-certified technicians with specialized training in:

- Mold inspection and comprehensive assessment

- Moisture investigation and source identification

- Proper containment and occupant safety protocols

- EPA-approved treatment methodologies and products

- Fort Wayne specific building and climate considerations

- Prevention strategy development for local conditions

- Commercial property remediation minimizing business disruption

We invest in professional equipment providing capabilities unavailable to property owners:

- Infrared thermal imaging cameras revealing hidden moisture patterns

- Professional moisture meters and hygrometers providing precise measurements

- Industrial dehumidifiers and air movers for thorough structural drying

- HEPA air scrubbers creating proper containment and air quality control

- Specialized antimicrobial application equipment ensuring thorough treatment

- Documentation equipment creating comprehensive project records

Every remediation project receives comprehensive professional treatment:

- Detailed initial assessment with complete moisture mapping identifying all problem areas

- Clear remediation plan addressing current mold and preventing future problems

- Proper containment preventing spore spread during remediation work

- Complete removal of contaminated porous materials ensuring elimination

- Professional antimicrobial treatment of all affected surfaces

- Thorough structural drying verified with moisture meter readings

- Post-remediation clearance testing verifying successful completion

- Written documentation supporting insurance claims or property transactions

- Prevention recommendations specific to your property and situation

- Warranties providing peace of mind about long-term results

We understand the stress, health concerns, and business implications accompanying mold problems. Our team responds quickly to requests, communicates clearly throughout projects, explains technical information in understandable terms, works efficiently minimizing disruption, and delivers results you can verify and trust.

Jennifer’s experience demonstrates the value of professional intervention. After 18 months of unsuccessful attempts, substantial expenses, tenant loss, and ongoing frustration, professional remediation resolved her problem permanently in less than two weeks. Her building has remained mold-free for three years. The comprehensive documentation helped her secure a new tenant quickly at favorable rent. The investment protected her property value and eliminated liability concerns.

Professional mold remediation represents an investment in your property value, occupant health, liability protection, and peace of mind. The comprehensive approach addresses not just current visible mold but underlying causes and future prevention, delivering lasting value.

Frequently Asked Questions

How quickly does mold grow after water damage occurs?

Mold spores exist everywhere in the environment and begin germinating within 24 to 48 hours when conditions become favorable (moisture, organic material, appropriate temperature). Visible colonies appear within 7 to 14 days depending on conditions. This rapid growth timeline makes immediate water damage response critical for mold prevention.

Can professional remediation guarantee mold will never return?

Professional remediation eliminates existing mold and addresses underlying causes preventing recurrence. Mold can return if new moisture sources develop, prevention strategies aren’t maintained, or new water damage occurs. Following professional recommendations for maintenance and prevention, combined with addressing any new water issues promptly, prevents recurrence. Reputable companies offer warranties against regrowth when recommendations are followed.

Should I test for mold before professional remediation?

Testing isn’t always necessary when visible mold exists requiring remediation regardless of species. Testing helps when: mold is suspected but not visible, verifying remediation success, identifying specific species for health concerns, supporting insurance claims, or addressing disputes. Professionals recommend testing when it provides actionable information affecting decisions or verification.

What should commercial property owners tell tenants about mold remediation?

Communicate openly about timelines, access requirements, noise or disruption expectations, and temporary relocation if necessary. Provide information about containment measures protecting them from exposure. Share documentation of successful completion. Open communication prevents concerns, maintains good relationships, and demonstrates proper response to issues.

Does homeowners or commercial property insurance cover mold remediation?

Coverage depends on cause and specific policy terms. Insurance typically covers mold resulting from sudden accidental water damage like burst pipes, storm damage, or appliance failures. It usually excludes mold from maintenance issues, gradual leaks, flooding, or pre-existing conditions. Review specific policy language or consult your insurance agent. Professional remediation companies provide documentation supporting covered claims.

How long does professional commercial property mold remediation take?

Small projects typically require 3 to 5 days including assessment, remediation, and verification. Medium projects span 5 to 10 days. Large projects may require 2 to 4 weeks depending on extent, required repairs, drying time, and reconstruction needs. Timeline varies based on specific circumstances. Professionals work efficiently minimizing business disruption and provide accurate schedules after initial assessment.

What should I look for when choosing a mold remediation company?

Verify: IICRC certification, appropriate insurance and bonding, local references, documented methodology following industry standards, clear pricing and scope of work, post-remediation verification testing inclusion, written warranties, and clear communication. Avoid companies offering unusually low prices without clear explanations or those pushing unnecessary services.

Can mold cause structural damage to buildings?

Yes. Mold growth indicates moisture presence sufficient to support wood rot and decay. Long-term moisture exposure degrades structural wood members, weakens drywall and ceiling materials, damages flooring systems, and compromises building integrity. This structural damage costs substantially more to address than mold itself. Professional remediation includes structural assessment identifying any damage requiring repair.

What’s the difference between mold remediation and mold removal?

Mold removal refers only to cleaning visible mold growth. Mold remediation includes comprehensive treatment: identifying and correcting moisture sources, removing contaminated materials, treating affected areas, controlling air quality during work, preventing recurrence, and verification testing. Remediation addresses complete problems rather than just visible symptoms, delivering permanent rather than temporary results.

Should I try cleaning small mold areas myself before calling professionals?

Small surface areas on non-porous materials (under 10 square feet on tile, glass, or sealed surfaces) can be cleaned with proper protection and products. However, recurring growth, porous material contamination, hidden growth, or occupant health symptoms require professional assessment. Attempting DIY remediation of situations beyond your capabilities wastes money and allows problems to worsen. When uncertain, professional assessment costs less than failed DIY attempts.

Conclusion

Mold recurrence after cleaning represents one of the most frustrating problems Fort Wayne property owners face. Surface cleaning methods cannot address subsurface hyphae networks that regenerate visible growth repeatedly. Active moisture sources sustain this cycle regardless of cleaning frequency, product selection, or homeowner determination.

Professional mold remediation succeeds where DIY methods fail by addressing complete problems rather than just visible symptoms. Comprehensive moisture investigation using specialized equipment identifies all water sources including those hidden inside building assemblies. Complete correction of moisture sources stops the water supply sustaining mold growth. Proper containment prevents contamination spread during remediation work. Thorough removal of contaminated materials eliminates mold reservoirs that surface cleaning cannot reach. Industrial air filtration protects air quality. EPA-approved antimicrobials treat remaining surfaces. Post-remediation verification testing provides objective confirmation of success. Prevention strategies stop future problems.

The investment in professional services delivers permanent resolution, protects occupant health, prevents progressive property damage, eliminates liability concerns, maintains property values, and ends the expensive frustrating cycle of recurring problems. Your property and its occupants deserve solutions that work definitively rather than temporarily.

If you’re experiencing recurring mold growth in your Fort Wayne area property, stop wasting time, money, and effort on ineffective temporary measures. Contact PuroClean Disaster Restoration of West Fort Wayne at (260) 263-9788 for comprehensive professional assessment and permanent mold remediation. Our certified technicians provide rapid response, efficient work, documented results, and guaranteed solutions protecting your property and occupant health.