Table of Contents

Water damage restoration in Roslyn requires a systematic nine-step approach: immediate safety assessment, emergency water extraction within the first hour, moisture detection using thermal imaging and meters, complete structural drying over 3-7 days, antimicrobial treatment to prevent mold, air quality restoration, damage assessment and documentation, professional reconstruction, and final verification. Professional services average $2,000-$8,000 depending on severity, but DIY attempts often lead to hidden moisture, mold growth, and structural deterioration costing $15,000-$30,000 to correct. Response within the first 24 hours reduces damage by up to 80% compared to delayed action.

Introduction: When Disaster Strikes Your Roslyn Home

It happened to the Johnsons on Willow Lane last February. A routine Sunday afternoon turned into a homeowner’s nightmare when their second-floor bathroom pipe burst while they were out running errands. By the time they returned three hours later, water had cascaded through their master bedroom, destroyed the kitchen ceiling below, and pooled in their finished basement. The damage? Over $18,000 in restoration costs.

But here’s what made their situation different from countless similar stories; they called professional restoration services within 30 minutes of discovering the damage. That single decision saved them an estimated $12,000 in additional costs they would have faced if they’d waited until Monday morning or attempted DIY cleanup.

Water damage strikes Roslyn homes with alarming frequency. Located in Montgomery County, this charming Pennsylvania community experiences the perfect storm of risk factors; aging housing stock built largely between the 1940s and 1970s, harsh winters that regularly drop below freezing, spring flooding from seasonal storms, and infrastructure approaching or exceeding design lifespan.

The statistics paint a concerning picture. According to insurance industry data, one in 50 Roslyn homeowners files a water damage claim each year. The average claim exceeds $9,500, and that number only reflects insured losses; it doesn’t include unreported damage, partial repairs, or long-term issues like mold that develop later.

What many Roslyn residents don’t realize is that water damage restoration isn’t just about removing visible water and drying surfaces. It’s a complex, multi-step process requiring specialized equipment, technical knowledge, and strict adherence to industry protocols. Miss a single step or execute it improperly, and you’re left with hidden moisture that turns into mold, warped structural members, and deteriorating building materials.

This comprehensive guide walks you through each critical step of professional water damage restoration in Roslyn, explaining not just what happens but why each phase matters. You’ll learn what to expect during the process, how to evaluate restoration companies, what insurance covers, and most importantly, how to prevent water damage before it happens.

Whether you’re currently dealing with water damage, want to be prepared for potential future incidents, or are simply protecting your investment through knowledge, this guide provides the expertise you need.

1. Why Roslyn Properties Face Unique Water Damage Risks

Understanding your specific risk factors is the first step in protection and preparedness. Roslyn’s particular characteristics create a unique risk profile that every homeowner should understand.

Geographic and Climate Factors

Pennsylvania Weather Extremes: Roslyn experiences the full range of Pennsylvania’s challenging climate. Winter temperatures regularly drop to 20°F or lower, while summer humidity levels reach 70-80%. This dramatic swing creates constant stress on plumbing systems, building materials, and drainage infrastructure.

Freeze-Thaw Cycles: Unlike regions with sustained freezing temperatures, Roslyn experiences repeated freeze-thaw cycles throughout winter. Pipes freeze at night, thaw during the day, then refreeze. This cycle causes expansion and contraction that weakens pipe walls, eventually leading to catastrophic failures.

Spring Storm Patterns: March and April bring heavy rainfall to Roslyn, often 4-6 inches in a single storm event. When this combines with snowmelt from the Perkiomen Creek watershed, the result is overwhelmed storm drains, saturated soil, and basement flooding.

Humidity Challenges: Summer humidity creates perfect conditions for condensation on cold water pipes, in crawl spaces, and in poorly ventilated areas. Over time, this condensation causes hidden water damage that goes unnoticed until mold appears or structural damage becomes visible.

Infrastructure and Housing Characteristics

Housing Age: The majority of Roslyn homes were built between 1945 and 1975. This means plumbing systems are 50-80 years old; far beyond the 50-year lifespan of galvanized steel pipes or the 25-year expectancy of polybutylene plumbing installed in the 1970s-80s.

Foundation Types: Many Roslyn homes sit on stone or block foundations common to mid-century construction. While durable, these foundations were often built without modern waterproofing techniques. Mortar deteriorates over time, creating pathways for water intrusion.

Original Drainage Systems: Homes built 50+ years ago often have inadequate or deteriorated drainage systems. Clay tile drains crack and collapse, original grading has settled allowing water to pool against foundations, and downspout systems discharge too close to homes.

Basement Finishing: Many Roslyn homeowners have finished their basements, adding living space and value. However, this also means that water intrusion affects valuable finished areas rather than bare concrete, multiplying damage costs.

Common Water Damage Scenarios in Roslyn

Burst Pipe Emergencies: During extreme cold snaps, Roslyn fire departments respond to dozens of burst pipe emergencies. Pipes in exterior walls, unheated attics, and crawl spaces are particularly vulnerable. A single burst pipe releases 400-500 gallons per hour; enough to destroy entire floors within hours.

Sump Pump Failures: Nearly 60% of Roslyn homes have sump pumps to manage groundwater. When pumps fail during heavy rain (often due to power outages), basements flood rapidly. The typical Roslyn basement can fill with several inches of water in under an hour during major storms.

Roof Leaks: Aging roofs combined with ice dams in winter and storm damage year-round create frequent leak scenarios. Water enters attics, travels along rafters, and appears in living spaces far from the actual entry point, making detection difficult.

Appliance Failures: Water heaters average 10-15 years; washing machines about 12 years; dishwashers 10-12 years. With Roslyn’s aging housing stock, appliances are often original to renovations done decades ago. When supply lines or the appliances themselves fail, the results are catastrophic.

Toilet Overflows: Second-floor toilet overflows are particularly destructive, cascading through ceilings and affecting multiple levels. Category 3 contamination makes these scenarios both dangerous and expensive to remediate.

Seasonal Risk Patterns

Winter (December-February): Highest risk of burst pipes, ice dam formation, and heating system failures. Cold snaps below 20°F trigger emergency calls.

Spring (March-May): Peak flooding season as snowmelt combines with spring rains. Overwhelmed drainage systems and saturated soil lead to basement flooding.

Summer (June-August): High humidity creates condensation issues. Air conditioning condensate line clogs and summer storm damage increase.

Fall (September-November): Transitional weather creates unique challenges. Early freezes catch unprepared homes, while hurricane remnants bring flooding rains.

Understanding these risks helps Roslyn homeowners prepare. The same factors affecting individual homes create community-wide challenges addressed in resources like water damage restoration in Center Square, where similar housing stock and weather patterns create comparable vulnerabilities.

2. Step 1: Immediate Safety Assessment and Emergency Response

The moments immediately following water damage discovery are critical. Your actions in the first few minutes can prevent injury, minimize damage, and set the stage for successful restoration.

Personal Safety First

Electrical Hazards: Water and electricity are a lethal combination. If water has reached electrical outlets, appliances, circuit breakers, or any electrical equipment, do not enter the affected area. Standing water can conduct electricity across entire rooms, creating deadly zones invisible to the eye.

If you must enter a flooded area, first shut off power at the main circuit breaker. If the breaker panel is in the flooded area or you’re unsure how to safely disconnect power, wait for professionals. Your life is worth more than any property.

Structural Integrity: Water adds enormous weight to building materials. Soaked ceiling drywall can weigh 10 times its dry weight. This added load can cause collapse without warning. Look for sagging ceilings, bulging walls, or warped floors. If you observe any of these, evacuate and call professionals immediately.

Contamination Risks: Not all water is equal. Clean water from a supply line is relatively safe, but water from toilet overflows, sewage backups, or flooding contains pathogens, bacteria, and potentially dangerous chemicals. Never wade through or contact potentially contaminated water without proper protective equipment.

Slip and Fall Hazards: Wet floors create dangerous slip hazards, especially on tile, laminate, or hardwood surfaces. If you must walk in affected areas, wear rubber-soled shoes and move cautiously.

Emergency Mitigation Actions

Stop the Water Source: If safe to do so, stop water flow. For appliance-related flooding, turn off the specific appliance and its water supply valve. For pipe bursts, shut off the main water valve; know where this is located before emergencies occur.

Document Initial Damage: Before touching anything, use your smartphone to photograph and video all affected areas. Capture wide shots showing overall damage and close-ups of specific items, water levels, and the source if identifiable. This documentation is invaluable for insurance claims.

Contact Emergency Services: Call 911 if there’s any risk to life, electrical hazards you cannot safely address, or structural concerns. For water damage without immediate danger, contact professional restoration services immediately. Most companies offering water damage restoration in Roslyn provide 24/7 emergency response with guaranteed arrival times.

Call Your Insurance Company: Contact your insurance agent or company claims line immediately. Many policies require notification within 24-48 hours. Ask specifically about emergency mitigation coverage; most policies cover reasonable emergency expenses to prevent further damage.

Protecting Valuables and Contents

Remove Portable Items: If safe, move furniture, electronics, documents, and valuables from affected areas to dry locations. Elevate items that cannot be moved by placing wood blocks or aluminum foil under legs. This prevents additional absorption and dye transfer from wet carpet to furniture.

Electronics and Documents: Water and electronics don’t mix. Immediately unplug and relocate computers, televisions, and appliances. For important documents, photographs, or irreplaceable items, move them to safe, dry areas. If documents are wet, freeze them immediately; this prevents degradation and gives you time to arrange professional document restoration.

High-Value Items: Artwork, antiques, collectibles, and other high-value items require special handling. Don’t attempt DIY drying; improper techniques cause irreversible damage. Professional contents restoration specialists have techniques and equipment to save items that appear destroyed.

What Not to Do

Don’t Use Household Vacuums: Regular vacuum cleaners are not designed for water extraction. Using them creates electrical hazards and damages the vacuum. Use wet/dry shop vacuums designed specifically for water.

Don’t Ignore Standing Water: Even an inch of standing water contains hundreds of gallons that continue causing damage every minute. While tempting to wait for professionals, removing standing water yourself (if safe) prevents additional absorption into floors and walls.

Don’t Use Electrical Appliances: Hair dryers, space heaters, or household fans in wet areas create electrical hazards. Professional air movers and dehumidifiers are designed for wet environments; household equipment is not.

Don’t Delay Professional Help: Every hour of delay increases damage exponentially. Within 24 hours, drywall begins swelling, metal surfaces tarnish, and mold spores begin germinating. After 48 hours, mold growth accelerates and restoration costs increase by 40% or more.

Establishing Communication

Emergency Contacts: Have numbers readily available for:

- Water damage restoration professionals: (267) 834-5900

- Your insurance agent and company claims line

- Plumber (if water source requires repair)

- Electrician (if electrical systems are affected)

- Family or neighbors who can provide assistance

Coordinate Response: When professionals arrive, provide them with all relevant information; when damage was discovered, what you’ve done, insurance information, and any special concerns. Clear communication ensures efficient response.

The emergency response phase sets the foundation for everything that follows. Proper actions in these critical first moments can reduce total damage by 60-80%, potentially saving tens of thousands of dollars. Professional restoration companies experienced in water damage restoration in Roslyn have refined emergency response protocols to maximize property preservation while ensuring safety.

3. Step 3: Hidden Moisture Detection and Mapping

Visible water is only part of the problem. Water migrates through capillary action, wicking into walls, traveling through subflooring, and saturating insulation in areas far from the source. Hidden moisture is the primary cause of long-term damage, mold growth, and restoration failures.

Why Moisture Detection Matters

Invisible Damage: Studies show that only 40% of water damage is visible to the naked eye. The remaining 60% hides behind walls, under flooring, in ceiling cavities, and within structural members. Without proper detection, this moisture causes rot, mold, and deterioration over months or years.

Mold Prevention: Mold requires moisture, organic material, and time. If moisture remains in hidden areas, mold growth is inevitable. Once established, mold remediation can cost more than the original water damage restoration, easily reaching $5,000-$15,000 for whole-house scenarios.

Structural Integrity: Hidden moisture weakens structural members. Wood begins losing strength at 20% moisture content. By 30%, rot organisms activate. Structural repairs due to undetected moisture can cost $20,000-$50,000 or more.

Complete Drying: You cannot dry what you cannot find. Thorough moisture detection ensures drying equipment is properly placed and that all affected areas receive appropriate treatment.

Professional Detection Equipment

Moisture Meters: These handheld devices measure moisture content in building materials. Pin-type meters use electrical resistance between two pins inserted into materials. Non-invasive meters use electromagnetic waves to detect moisture without damaging surfaces. Professional technicians take readings at dozens of points, creating a moisture map of your property.

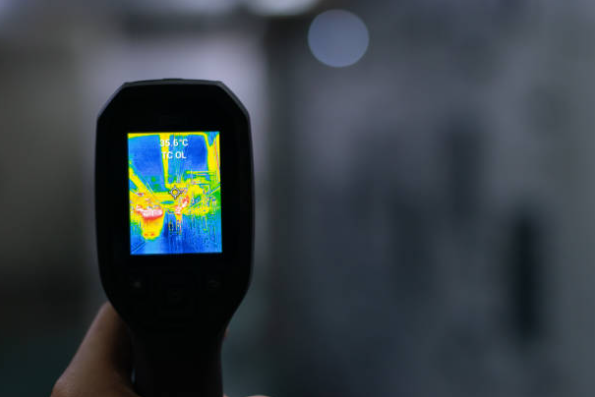

Infrared Thermal Cameras: These incredible tools visualize temperature differences invisible to the human eye. Since wet materials are cooler than dry materials, thermal cameras reveal moisture patterns behind walls, under floors, and in ceilings without any destructive investigation. They can detect moisture migration patterns, identify water sources, and verify complete drying.

Hygrometers: These measure relative humidity in air and materials. Specific humidity readings indicate how much moisture air can still absorb, determining optimal dehumidifier placement and settings.

Thermo-Hygrometers: Combined temperature and humidity meters provide the data necessary to calculate grains per pound (GPP) and specific humidity, determining precise drying goals and tracking progress.

Moisture Detection Process

Initial Survey: Technicians begin with visual inspection, identifying obvious damage and likely moisture migration patterns based on water source and building construction. This guides thorough investigation.

Comprehensive Scanning: Using thermal imaging, technicians scan all walls, ceilings, and floors in affected and adjacent areas. Water travels unpredictably, sometimes appearing in locations that seem unrelated to the source.

Moisture Mapping: Detailed measurements are taken at numerous points, creating a comprehensive map showing exact moisture levels throughout the property. This map guides drying equipment placement and provides baseline data for tracking progress.

Documentation: All readings are photographed, recorded, and provided to insurance companies. This documentation is critical for claim approval and provides evidence of thorough work.

Common Hidden Moisture Locations

Wall Cavities: Water enters wall cavities through top plates, travels down insulation, and accumulates at bottom plates. Without detection and drying, this moisture causes mold and rot hidden from view.

Subflooring: Water travels between flooring and subfloor, often affecting areas far from visible damage. This is particularly problematic under tile, vinyl, or laminate flooring that traps moisture.

Crawl Spaces: Water in crawl spaces goes unnoticed for extended periods. High humidity and poor ventilation create perfect mold-growing conditions.

Ceiling Cavities: Water from upper-floor incidents travels along joists, appearing in locations far from the source. Without thermal imaging, these migrations go undetected until mold appears or ceilings collapse.

Behind Baseboards and Trim: Water wicks up drywall and hides behind baseboards. This is particularly common with carpet flooding, where water absorbs into drywall behind trim.

Insulation: Wall and ceiling insulation acts like a sponge, absorbing and holding water long after visible areas dry. Wet insulation must be identified and often removed.

Setting Drying Goals

Detection establishes baseline readings for comparison. Drying goals for water damage restoration in Roslyn typically include:

- Wood Materials: 15% moisture content or lower

- Drywall: Below 1% moisture content

- Concrete: Below 3% moisture content for normal conditions

- Relative Humidity: 40-50% throughout affected areas

Professional restoration services track progress daily, adjusting equipment and techniques to achieve these goals efficiently. The same thorough approach benefits properties described in water damage restoration in Blue Bell, where similar construction styles create comparable detection challenges.

4. Step 4: Complete Structural Drying Process

Structural drying is both science and art, requiring understanding of psychrometrics (the science of air and moisture interaction), material properties, and environmental control. This phase typically takes 3-7 days but varies based on damage extent, materials, and environmental conditions.

The Science of Drying

Evaporation Process: Drying occurs through evaporation; liquid water converting to water vapor. This requires three conditions: heat (to accelerate molecular movement), airflow (to carry vapor away from surfaces), and low humidity (to create vapor pressure differential allowing moisture movement from materials to air).

Psychrometric Principles: The relationship between temperature, humidity, and air’s water-holding capacity drives drying. Warm air holds more moisture than cold air. Dry air pulls moisture from materials more effectively than saturated air. Professional drying manipulates these variables for optimal results.

Material-Specific Drying: Different materials dry at different rates. Non-porous materials like metal or glass dry quickly. Semi-porous materials like wood or plywood require several days. Porous materials like insulation or upholstery need extended time or replacement.

Dehumidification Importance: As air absorbs moisture from materials, it becomes saturated. Without dehumidification, the process stops. Dehumidifiers remove moisture from air, allowing continuous evaporation.

Professional Drying Equipment

High-Velocity Air Movers: Unlike household fans, professional air movers create focused, high-velocity airflow at specific angles. Axial air movers move large volumes at lower pressure; centrifugal air movers provide higher pressure and velocity. Proper placement creates airflow patterns that maximize evaporation across all surfaces.

Low-Grain Refrigerant (LGR) Dehumidifiers: These sophisticated machines reduce humidity to levels household dehumidifiers cannot achieve. LGR units can create relative humidity below 20%, dramatically accelerating drying. They’re also more energy-efficient than conventional units.

Desiccant Dehumidifiers: For cold environments (below 65°F) where refrigerant units lose efficiency, desiccant dehumidifiers use absorbent materials to remove moisture chemically. They work effectively across wide temperature ranges.

Specialty Drying Equipment: Depending on materials and situation, professionals may employ:

- Injection drying systems: Force warm, dry air into wall cavities

- Drying mats: Create suction against hardwood floors, extracting moisture without removal

- Heat drying systems: Controlled heating that accelerates evaporation without material damage

Drying Strategy Development

Assessment-Based Planning: Based on moisture detection results, material types, and damage classification, technicians develop customized drying plans specifying equipment types, quantities, placement, and estimated timeline.

Equipment Placement: Strategic placement is critical. Air movers are positioned to create overlapping airflow patterns, directing air across all wet surfaces. Dehumidifiers are centrally located to process maximum air volume. Equipment is elevated to protect against residual water and ensure optimal operation.

Environmental Control: Windows and doors may be opened or closed depending on outdoor conditions. In dry conditions, opening windows enhances air exchange. In humid conditions, closed environments allow better dehumidification control.

Monitoring and Adjustment: Professionals don’t just set equipment and leave. Daily visits include:

- Moisture readings at all baseline locations

- Equipment operation checks

- Airflow and humidity measurements

- Equipment repositioning based on drying progress

- Strategy adjustments to address stubborn moisture areas

Drying Timelines by Material

Carpet and Padding: Carpet can often be dried in 2-4 days with proper extraction and airflow. Padding typically requires replacement as it holds water, is difficult to fully dry, and provides ideal mold growth conditions once contaminated.

Hardwood Flooring: 5-10 days depending on wood type and water exposure duration. Engineered hardwood dries faster than solid hardwood. Cupping (edges higher than centers) often occurs initially but typically flattens as drying continues. Crowning (centers higher than edges) indicates over-drying or improper techniques.

Drywall: 3-7 days depending on saturation levels. Drywall wicks water from bottom to top; moisture detected 12 inches above the floor often requires drying to 24 inches to ensure complete dryness.

Structural Lumber: 7-14 days for significant saturation. Dimensional lumber (2x4s, 2x6s) dries relatively quickly, but larger timbers require extended time.

Concrete: 10-21 days for complete drying, though surface drying occurs much faster. Concrete holds significant moisture that slowly evaporates; rushing installation of floor coverings traps moisture and causes adhesive failure or mold growth.

Advanced Drying Techniques

Controlled Demolition: Sometimes selective material removal accelerates drying and reduces costs. Removing baseboards allows airflow behind drywall. Drilling small holes allows air circulation in wall cavities. Strategic cuts in water-damaged drywall enable cavity drying without whole-wall replacement.

Dehumidification Chambers: For contents or specialty materials, contained drying chambers provide controlled environments optimized for specific items; documents, artwork, electronics, furniture.

Negative Air Pressure: In contaminated water scenarios, creating negative air pressure prevents moisture and contaminants from migrating to unaffected areas while drying proceeds.

Verification of Complete Drying

Drying isn’t complete when materials feel dry. Professional verification includes:

- Moisture meter readings at or below target levels

- Relative humidity consistent throughout affected areas

- Thermal imaging showing uniform temperature (no cool wet spots)

- Comparison to unaffected areas showing similar readings

Only when all criteria are met is drying considered complete. This thoroughness prevents callback scenarios where moisture reappears, mold grows, or materials deteriorate after restoration is considered finished.

Effective drying makes the difference between successful restoration and ongoing problems. Resources on basement flooding cleanup service demonstrate these principles in action, showing how comprehensive drying prevents the chronic moisture issues that plague improperly restored basements.

5. Step 5: Antimicrobial Treatment and Sanitization

Water damage restoration isn’t complete with simply removing water and drying structures. Ensuring the environment is clean, safe, and protected against microbial growth is essential to occupant health and long-term property integrity.

Understanding Microbial Risks

Bacteria and Pathogens: Water, especially from Categories 2 and 3, contains bacteria that pose health risks. E. coli, Salmonella, and other pathogens cause illness through contact or inhalation. Even Category 1 water can develop bacteria if standing for 48+ hours.

Mold Spores: Mold spores are ubiquitous; they’re always in the air. Water damage creates the conditions (moisture and organic material) for germination and growth. Once established, mold releases additional spores, allergens, and sometimes mycotoxins into air.

Biofilm Development: Bacteria can form biofilms; protective layers that resist typical cleaning. These biofilms harbor pathogens and create ongoing contamination risks.

Long-Term Health Impact: Prolonged exposure to mold and bacteria causes respiratory issues, allergic reactions, headaches, fatigue, and in severe cases, serious illness. Children, elderly individuals, and those with compromised immune systems face elevated risks.

Professional Antimicrobial Products

EPA-Registered Solutions: Professional restoration uses EPA-registered antimicrobial and disinfectant products proven effective against target organisms. These aren’t household cleaners; they’re industrial-grade solutions with documented kill rates and proper application protocols.

Application-Specific Products: Different situations require different products:

- Quaternary Ammonium Compounds (Quats): Broad-spectrum antimicrobials effective against bacteria and some viruses

- Phenolics: Strong disinfectants for heavily contaminated areas

- Hydrogen Peroxide Derivatives: Effective against mold while being environmentally friendly

- Enzyme Cleaners: Break down organic matter that feeds microbial growth

Safety Considerations: Professional products require proper handling, personal protective equipment, and adherence to manufacturer guidelines. Improper use creates health hazards; proper use ensures safety and effectiveness.

Antimicrobial Application Process

Surface Preparation: Before antimicrobial application, surfaces must be cleaned of debris, sediment, and gross contamination. Antimicrobials work on clean surfaces; dirt and debris harbor organisms and prevent product contact.

Application Methods:

- Spray Application: For walls, ceilings, and large surface areas

- Fogger Application: Creates fine mist reaching hidden areas and providing comprehensive coverage

- Wipe Application: For contents, furniture, and items requiring gentle treatment

Dwell Time: Antimicrobials require specific contact time with surfaces to be effective. Professional application ensures products remain wet on surfaces for required dwell times; typically 5-10 minutes depending on product.

Multi-Stage Treatment: Severe contamination may require multiple applications; initial broad-spectrum treatment, specialized mold treatment, final protective application.

Mold-Specific Treatments

Preventive Application: Even when visible mold isn’t present, preventive antimicrobial treatment inhibits future growth during and after drying.

Active Growth Treatment: When mold colonies are visible, treatment includes:

- Physical removal of contaminated porous materials (drywall, insulation)

- HEPA vacuuming to capture spores

- Antimicrobial application to remaining surfaces

- Encapsulation of stained but structurally sound materials

Air Scrubbing: HEPA air scrubbers capture airborne mold spores released during treatment and remediation, preventing spread to unaffected areas and protecting air quality.

Deodorization

Water damage often creates persistent odors from bacterial growth, sewage contamination, or trapped moisture. Professional deodorization includes:

Hydroxyl Generators: These produce hydroxyl radicals that neutralize odor molecules at the molecular level without harmful byproducts.

Ozone Treatment: In unoccupied spaces, ozone generators oxidize odor-causing compounds. Strict protocols ensure occupant safety.

Thermal Fogging: Deodorizing agents are heated and dispersed as fog, penetrating porous materials and neutralizing embedded odors.

Source Removal: Sometimes odors persist because source materials remain. Professional assessment determines when material removal is necessary rather than treating symptoms.

Safety Protocols

Personal Protective Equipment (PPE): Technicians wear appropriate PPE; gloves, respirators, eye protection; especially when dealing with Category 2 or 3 water.

Containment: In contaminated scenarios, plastic sheeting creates barriers preventing cross-contamination to unaffected areas.

Proper Disposal: Contaminated materials are bagged, sealed, and disposed following local regulations. This prevents spreading contamination during removal.

Air Quality Testing: For severe mold situations or when occupants report symptoms, professional air quality testing verifies successful remediation before reoccupation.

Verification of Effectiveness

Visual Inspection: No visible mold growth, staining, or contamination

Odor Elimination: No musty, sewage, or other unusual odors

Air Quality: Normal spore counts if testing was performed

Surface Testing: For severe cases, surface samples verify antimicrobial effectiveness

Comprehensive antimicrobial treatment ensures water damage restoration in Roslyn properties result in environments that are not just dry but genuinely safe for occupancy. The techniques employed mirror those in mold remediation in King of Prussia, where similar contamination concerns require equally thorough sanitization.

6. Step 6: Air Quality Restoration and Deodorization

Clean, safe air is fundamental to successful water damage restoration. Even after visible damage is repaired and surfaces are dried, air quality issues can persist, affecting occupant health and comfort.

Air Quality Concerns After Water Damage

Airborne Mold Spores: Drying and remediation processes disturb settled spores, releasing them into air. These invisible particles can trigger allergic reactions, respiratory issues, and other health problems.

Volatile Organic Compounds (VOCs): Mold and bacteria produce VOCs as metabolic byproducts. These chemicals create musty odors and can cause headaches, dizziness, and irritation.

Particulates: Disturbed dust, drywall particles, insulation fibers, and other materials become airborne during restoration, affecting respiratory systems.

Humidity Imbalance: Even after structural drying, indoor humidity levels may remain elevated or, conversely, over-dried from excessive dehumidification.

Professional Air Filtration

HEPA Air Scrubbers: High-Efficiency Particulate Air (HEPA) filters capture 99.97% of particles 0.3 microns or larger. This includes mold spores, bacteria, dust, and most airborne contaminants. Commercial air scrubbers process entire room volumes multiple times per hour.

Negative Air Machines: These create negative pressure in work areas, preventing contaminated air from migrating to clean areas. Filtered exhaust ensures contaminants don’t simply relocate.

Activated Carbon Filtration: Carbon filters absorb VOCs, odors, and chemical contaminants that HEPA filters miss. Combined HEPA and carbon filtration provides comprehensive air cleaning.

Air Exchange Rates: Professional calculations determine required air changes per hour (ACH) based on room size and contamination level, ensuring adequate filtration without over-processing.

Odor Elimination Techniques

Source Identification: Effective deodorization begins with identifying and eliminating odor sources. Masking odors without removing sources provides only temporary relief.

Hydroxyl Radical Technology: Hydroxyl generators produce radicals that break down odor molecules into harmless components; water vapor and carbon dioxide. This technology works continuously without requiring evacuation and leaves no residue.

Ozone Treatment: For severe odors in unoccupied spaces, ozone generators oxidize odor-causing compounds. Strict protocols include:

- Complete occupant and pet evacuation

- Sealing treated areas

- Calculated ozone concentration and exposure time

- Thorough ventilation before reoccupancy

- Air quality verification

Thermal Fogging: Heated deodorizing compounds become fine particles that penetrate porous materials; carpet, upholstery, drywall; neutralizing embedded odors. This technique reaches areas spray application cannot.

Encapsulation: For odors absorbed into materials that cannot be removed, encapsulation sealers trap odor molecules, preventing release into air.

Material-Specific Deodorization

Carpet and Upholstery: Deep extraction removes odor-causing residues, followed by enzyme treatments that break down organic matter, and finally protective treatments.

Wood Materials: Wood absorbs odors readily. Sanding affected areas, applying deodorizing sealers, and sometimes replacement are necessary for severe cases.

HVAC Systems: Odors can permeate ductwork and air handlers. Professional duct cleaning, coil treatment, and filter replacement address this source.

Contents: Furniture, clothing, books, and personal belongings require specialized cleaning; ozone chambers, thermal fogging, or professional laundering.

Humidity Normalization

Balanced Levels: Post-restoration, indoor humidity should stabilize at 30-50% relative humidity. This range prevents mold growth while maintaining comfort and protecting materials.

Dehumidifier Removal: Gradual removal of dehumidification equipment prevents humidity spikes. Monitoring continues several days after equipment removal.

Long-Term Humidity Control: If pre-existing humidity issues contributed to damage, recommendations for whole-house dehumidifiers, improved ventilation, or HVAC modifications may be provided.

Indoor Air Quality Testing

For severe water damage scenarios, particularly involving mold or sewage, professional air quality testing provides objective verification:

Spore Count Analysis: Air samples are analyzed for mold spore counts and types, comparing affected areas to outdoor baselines.

Bacteria Testing: In sewage-related damage, bacterial testing verifies successful sanitization.

VOC Analysis: Identifies specific chemicals contributing to odor or health complaints.

Clearance Testing: Final testing before project completion confirms air quality meets acceptable standards.

Long-Term Air Quality Maintenance

Ventilation Improvements: Recommendations for exhaust fans, air exchangers, or HVAC upgrades to maintain good air quality.

Maintenance Plans: Regular HVAC filter changes, periodic duct cleaning, and humidity monitoring prevent future issues.

Early Warning Systems: Installation of humidity monitors or air quality sensors provides early alerts to developing problems.

Comprehensive air quality restoration ensures that water damage restoration in Roslyn properties doesn’t just look good; they’re genuinely healthy environments. This attention to invisible threats distinguishes professional restoration from superficial repairs.

7. Step 7: Comprehensive Damage Documentation

Thorough documentation serves multiple critical purposes; insurance claim support, project tracking, quality assurance, and legal protection. Professional restoration companies treat documentation as seriously as physical restoration work.

Insurance Documentation Requirements

Initial Damage Assessment: Detailed reports document pre-restoration conditions including:

- Extent of water damage by room and area

- Water category and class classification

- Moisture readings at baseline

- Affected materials inventory

- Photographic evidence

Daily Progress Reports: Throughout restoration, daily logs record:

- Equipment in use and locations

- Moisture readings showing drying progress

- Work performed

- Materials removed or replaced

- Any complications or changes

Final Documentation: Completion reports include:

- Before and after photographs

- Final moisture readings proving complete drying

- Materials replaced or repaired

- Equipment usage logs (for billing verification)

- Verification that industry standards were met

Itemized Estimates: Detailed estimates break down labor, materials, equipment, and other costs. This transparency helps insurance companies process claims efficiently and protects homeowners from surprise charges.

Photographic and Video Evidence

Before Photos: Capturing damage before any mitigation work begins is critical. Multiple angles, overall views, and detail shots document the full scope for insurance adjusters who may never visit the property.

Process Documentation: Photos throughout restoration show:

- Equipment placement

- Material removal

- Hidden damage discovered

- Repair techniques employed

- Progress at various stages

After Photos: Final images showing completed restoration allow before/after comparison, demonstrating the work’s quality and thoroughness.

Thermal Imaging Records: Infrared images showing hidden moisture, drying progress, and final verification provide powerful visual evidence supporting thorough restoration.

Moisture Reading Logs

Baseline Measurements: Initial readings establish damage extent and create benchmarks for measuring progress.

Daily Tracking: Readings at the same locations each day show drying curves; the rate at which moisture decreases. Flat curves indicate problems requiring strategy adjustments.

Drying Verification: Final readings below target levels prove complete drying. These records protect both homeowner and restoration company from future moisture-related claims.

Comparative Analysis: Readings from unaffected areas provide control measurements, showing what “normal” looks like in your specific property.

Protecting Your Interests

Personal Inventory: While restoration companies document structural damage, homeowners should separately inventory contents damage including:

- Description of each damaged item

- Original purchase price and date

- Estimated replacement cost

- Photos of damage

- Receipts or proof of ownership for valuable items

Communication Logs: Keep records of all communications:

- Insurance company contacts, names, dates, topics

- Contractor conversations and commitments

- Adjuster visit dates and discussions

- Any disputes or disagreements

Receipts and Expenses: Save receipts for:

- Emergency mitigation expenses

- Temporary housing if required

- Food expenses if cooking facilities are unavailable

- Any out-of-pocket costs related to the incident

Scope Changes: Document any changes to original restoration scope, including reasons for changes and approvals received.

Creating Your Own Documentation

While professionals provide comprehensive documentation, homeowners should:

Maintain Photo Archives: Take your own photos throughout the process. Different perspectives and timing can capture details professionals miss.

Journal the Experience: Written notes about timeline, concerns, conversations, and observations create valuable records if disputes arise.

Understand Reports: Review all documentation carefully. Ask questions about anything unclear. This ensures you understand what work was performed and why.

Retain Copies: Keep complete copies of all documentation; estimates, contracts, daily logs, invoices, insurance correspondence. Organize chronologically for easy reference.

Documentation Technology

Digital Platforms: Many restoration companies use specialized software creating real-time reports accessible to homeowners and insurance companies. These platforms provide transparency and streamline communication.

Cloud Storage: Digital documentation is backed up to cloud storage, ensuring records aren’t lost if additional damage occurs.

Mobile Access: Smartphone apps allow technicians to record data on-site, improving accuracy and timeliness of documentation.

Legal Protections

Scope of Work Agreements: Written agreements defining work to be performed protect both parties. Detailed scopes prevent misunderstandings about what’s included.

Change Orders: Any scope changes should be documented in writing with cost adjustments clearly stated and approved.

Warranties: Professional restoration includes warranties on workmanship. Ensure warranty terms are clearly documented.

Lien Waivers: As payments are made, obtain lien waivers protecting your property from contractor claims.

Comprehensive documentation is invisible to casual observers but provides critical protection and peace of mind. It’s the difference between smooth insurance claim processing and months of disputes, between quality assurance and uncertainty about work performed.

8. Step 8: Professional Reconstruction and Restoration

After extraction, drying, and sanitization, reconstruction returns your property to pre-loss condition or better. This phase transforms disaster-damaged spaces back into the comfortable, functional home you remember.

Reconstruction Planning

Assessment of Necessary Repairs: Once materials are dry, comprehensive assessment determines what must be replaced versus what can be restored:

- Drywall with water stains or delamination requires replacement

- Structurally sound but stained wood materials may be sanded and refinished

- Carpet with Category 1 damage might be salvaged; Category 2 or 3 requires replacement

- Flooring assessment based on water exposure duration and material type

Matching Materials: Quality restoration uses materials matching original construction:

- Same drywall thickness and type

- Matching flooring species, grade, and finish

- Identical trim profiles and dimensions

- Paint color matching

Code Compliance: Repairs must meet current building codes even if original construction predated code changes. This may require upgrades that insurance companies sometimes cover under “ordinance or law” provisions.

Timeline Development: Realistic schedules account for material delivery, subcontractor availability, and proper drying time for applied materials like joint compound, paint, and adhesives.

Structural Repairs

Framing Replacement: Water-damaged studs, joists, or rafters require replacement when moisture content exceeds 19% or when rot or deterioration is evident.

Subfloor Reconstruction: Water-damaged subflooring often requires replacement, especially particle board or OSB products that swell and delaminate when wet.

Foundation Work: Significant water intrusion may reveal foundation issues requiring repair before finishing work proceeds.

Load-Bearing Considerations: Structural repairs, particularly on load-bearing walls or supports, require engineered solutions and possibly building permits.

Finish Work

Drywall Replacement: Systematic process of:

- Removing damaged sections

- Installing new drywall

- Taping and mudding joints

- Sanding smooth

- Priming and painting

Flooring Installation: Depends on material type:

- Hardwood installation and finishing

- Carpet and padding replacement

- Tile setting and grouting

- Vinyl or laminate installation

Trim and Millwork: Replacing baseboards, crown molding, door casings, and other trim work to match existing profiles.

Painting: Professional painting matching existing colors, finishes, and textures. May involve multiple coats and specialty techniques for texture matching.

Specialty Restoration

Custom Woodwork: Damaged custom cabinetry, built-ins, or millwork may require carpenter replication of original pieces.

Decorative Elements: Ornamental plaster, medallions, or other architectural details need skilled craftsmen for authentic restoration.

Historic Properties: Older homes may require specialty materials and techniques preserving historic character while meeting modern codes.

Contents Restoration

Furniture Restoration: Professional cleaning, refinishing, or reupholstering of damaged furniture when replacement costs exceed restoration.

Electronics Recovery: Specialized electronics restoration can sometimes save water-damaged computers, TVs, and appliances through disassembly, cleaning, and testing.

Document Recovery: Freeze-drying and other techniques can save water-damaged documents, photographs, and books.

Textile Cleaning: Professional laundering and treatment of clothing, linens, and other textiles.

Quality Control

Inspection Checklists: Systematic verification that all work meets professional standards:

- Smooth, even surfaces

- Tight joints and seams

- Level, plumb installation

- Color matching

- Proper function of all systems

Moisture Verification: Final moisture readings throughout reconstructed areas verify that drying was complete and moisture hasn’t returned.

Air Quality Check: Ensuring no construction dust, paint fumes, or other contaminants remain.

Client Walkthrough: Detailed walkthrough with homeowner addressing any concerns before project completion.

Upgrade Opportunities

While insurance typically covers replacement of like kind and quality, water damage restoration sometimes presents opportunities for improvements:

Better Materials: Upgrading to water-resistant drywall in bathrooms or basements, higher-quality flooring, or improved insulation.

Preventive Installations: Adding water detection alarms, improved drainage, or waterproofing while areas are open.

Modernization: If codes require updates, you might upgrade electrical, plumbing, or HVAC simultaneously.

Aesthetics: Matching damaged rooms creates opportunity to refresh adjacent areas, creating cohesive design.

Project Completion

Final Documentation: Complete before/after photos, warranties on work performed, and care instructions for new materials.

System Verification: Testing plumbing, electrical, and HVAC systems affected by work.

Cleanup: Complete removal of debris, thorough cleaning, and proper disposal.

Keys and Access: Return of all keys, entry codes, and access information used during restoration.

The reconstruction phase is where professional craftsmanship shines. Quality work is invisible; new work seamlessly integrates with existing construction. This attention to detail distinguishes excellent water damage restoration in Roslyn from mere adequacy.

9. Step 9: Final Verification and Quality Assurance

The final step ensures every aspect of restoration meets professional standards, providing you confidence in the work performed and protection against future issues.

Comprehensive Final Inspection

Visual Assessment: Detailed examination of all repaired areas checking:

- Paint quality; even coverage, no streaks, brush marks, or roller marks

- Flooring; level installation, tight seams, matching patterns

- Trim work; tight joints, proper alignment, consistent reveals

- Ceiling and wall surfaces; smooth finish, no visible seams or repairs

Functional Testing: Verification that all systems work properly:

- Plumbing fixtures operate without leaks

- Electrical outlets and switches function correctly

- HVAC vents provide appropriate airflow

- Doors and windows open, close, and latch properly

Moisture Verification: Final moisture readings throughout restored areas proving:

- All materials at or below normal levels

- No hidden moisture in wall cavities or subflooring

- Humidity levels appropriate for the season

- Comparison to unaffected areas showing similar readings

Air Quality Confirmation: Ensuring:

- No unusual odors

- Normal relative humidity

- Air quality testing results (if performed) show acceptable levels

Documentation Review

Complete Records: Verifying all documentation is present and accurate:

- Initial assessment reports

- Daily progress logs

- Moisture reading records

- Photographic evidence

- Equipment usage logs

- Materials used

- Final invoice

Warranty Information: Clear documentation of:

- Warranty coverage and duration

- What’s covered versus excluded

- Claim procedures if issues arise

- Contact information for warranty service

Insurance Documentation: Ensuring all required documents for insurance claim are complete:

- Final invoice matching approved scope

- Proof of code compliance

- Certificates of completion

- Lien waivers if applicable

Client Education

Preventive Maintenance: Guidance on preventing future water damage:

- Regular plumbing inspections

- Seasonal winterization procedures

- Drainage maintenance

- Early warning sign recognition

Material Care: Instructions for maintaining newly installed materials:

- Hardwood floor care

- Carpet cleaning recommendations

- Paint and finish maintenance

- Warranty preservation requirements

System Operation: If new equipment was installed (dehumidifiers, sump pumps, etc.), training on:

- Proper operation

- Maintenance requirements

- Troubleshooting common issues

- When to call for service

Verification of Satisfaction

Client Walkthrough: Detailed walkthrough with homeowner:

- Reviewing all work performed

- Demonstrating system operation

- Addressing any concerns

- Making punch-list of minor items requiring attention

Addressing Concerns: Professional companies don’t consider work complete until you’re satisfied. Any items not meeting standards are promptly addressed.

Final Acceptance: Formal acceptance only after you’ve verified all work meets your expectations.

Post-Restoration Support

Follow-Up Contacts: Professional companies contact clients:

- Within one week to address any immediate concerns

- At 30 days to ensure no moisture has returned

- At 90 days for final verification

- Annually to check on long-term satisfaction

Ongoing Availability: Quality restoration companies remain available for questions, concerns, or warranty issues long after project completion.

Additional Resources: Providing information on:

- Preventive maintenance

- Seasonal preparation

- Emergency contact information

- Related services if future needs arise

Industry Standards Compliance

IICRC Standards: Verification that all work adhered to Institute of Inspection, Cleaning and Restoration Certification standards for water damage restoration.

Building Code Compliance: Ensuring all repairs meet applicable building codes and passed required inspections.

Insurance Requirements: Confirmation that work meets insurance company standards and claim requirements.

Long-Term Protection

Maintenance Plans: Optional maintenance agreements providing:

- Annual inspections

- Preventive maintenance

- Priority emergency response

- Discounted services

Monitoring Services: For high-risk properties, remote monitoring options:

- Water detection sensors

- Humidity monitoring

- Sump pump operation alerts

- Freeze detection

Quality Guarantee

Professional water damage restoration in Roslyn includes guarantees covering:

- Workmanship for specified periods (typically 1-2 years)

- Materials defects as per manufacturer warranties

- Moisture return (if restoration was performed correctly, moisture shouldn’t return)

- Air quality (no mold growth in professionally restored areas)

This final verification phase provides peace of mind that restoration was performed to the highest standards and that your property is truly returned to pre-loss condition; or better.

10. Real Roslyn Case Studies and Success Stories

Understanding restoration through real scenarios helps illustrate these principles in action. Here are three actual cases (with names changed) from Roslyn properties.

Case Study 1: The Winter Pipe Burst

The Situation: The Anderson family returned from a week-long vacation in January to find their home flooded. An exterior wall pipe in their master bathroom had frozen and burst three days earlier. Water had flowed for approximately 72 hours, affecting their master bedroom, two guest rooms, the kitchen directly below, and the finished basement.

The Damage: Class 3 water damage affecting approximately 2,000 square feet across three levels. Category 1 clean water that had begun degrading to Category 2 due to time. Estimated damage: $22,000.

The Response: They called emergency restoration services within 15 minutes of discovering damage. Technicians arrived in 45 minutes and immediately began:

- Safety assessment and power shut-off to affected areas

- Emergency water extraction removing 800+ gallons

- Content removal and protection

- Initial moisture mapping using thermal imaging

The Process:

- Days 1-2: Continuous extraction, content pack-out, affected materials removal (soaked insulation, ceiling drywall)

- Days 3-6: Structural drying using 8 air movers and 2 LGR dehumidifiers

- Day 7: Final moisture verification; all materials at target levels

- Days 8-14: Reconstruction including drywall, insulation, painting, flooring

- Day 15: Final walkthrough and acceptance

The Outcome: Total restoration cost: $18,500 (less than initial estimate due to successfully saving hardwood floors thought to require replacement). Insurance covered $17,800 after $1,000 deductible. Family moved back home Day 16. Follow-up at 30 days showed no moisture return or issues.

Key Success Factors: Immediate professional response, thorough moisture detection preventing hidden damage, proper drying preventing mold, quality reconstruction.

Case Study 2: The Appliance Failure

The Situation: The Roberts family was home when their washing machine supply line burst on a Sunday afternoon. They immediately shut off the water but not before significant flooding affected their first-floor laundry room, adjacent kitchen, and crawl space below.

The Damage: Class 2 water damage affecting approximately 600 square feet. Category 1 clean water. Estimated damage: $6,500.

The Response: They initially attempted DIY cleanup using shop vacuums and household fans. After two days, they noticed musty odors and called professionals. Moisture meter readings revealed hidden saturation the DIY efforts hadn’t addressed.

The Process:

- Day 1 (professional intervention): Comprehensive moisture mapping revealing water in wall cavities and subflooring undetected by homeowners

- Days 1-2: Professional extraction of hidden moisture, removal of damaged materials

- Days 3-5: Structural drying with professional equipment

- Days 6-9: Antimicrobial treatment, reconstruction

- Day 10: Completion

The Outcome: Total cost: $8,200 (higher than initial estimate due to hidden damage from DIY delay). Two-day DIY attempt allowed mold spores to germinate requiring additional antimicrobial treatment and material removal. Insurance covered $7,500 after $750 deductible.

Key Lessons: DIY cleanup appeared successful but missed hidden moisture. The $1,700 increase from delayed professional intervention far exceeded the cost of immediate professional response. Hidden damage is why professional moisture detection is critical.

Case Study 3: The Basement Flood

The Situation: During a severe spring storm, the Martinez family’s sump pump failed due to power outage. Their finished basement flooded with approximately 4 inches of water affecting their family room, home office, bathroom, and storage areas.

The Damage: Class 3 water damage affecting 1,200 square feet of finished basement. Category 2 gray water (sump discharge). Estimated damage: $15,000.

The Response: Called emergency services during the storm. Technicians arrived within 90 minutes and began emergency response even as rain continued.

The Process:

- Storm night: Emergency extraction, content removal, initial containment

- Days 1-3: Continued extraction, removal of unsalvageable materials (carpet, padding, bottom 2 feet of drywall)

- Days 4-7: Structural drying and dehumidification

- Days 8-10: Antimicrobial treatment and air scrubbing

- Days 11-18: Complete reconstruction with upgrades (water-resistant drywall, upgraded sump pump with battery backup, water detection alarm)

- Day 19: Final completion

The Outcome: Total cost: $16,800 ($1,800 over initial estimate due to code-required electrical upgrades). Insurance covered $15,300 after $1,500 deductible. Upgrades included battery backup sump pump preventing future failures, water detection alarm for early warning, and improved drainage protecting investment.

Key Success Factors: Professional response despite ongoing storm, thorough Category 2 water protocols, strategic upgrades preventing recurrence.

11. Choosing Certified Restoration Professionals

The quality of your water damage restoration in Roslyn depends entirely on the company you choose. Here’s how to make that critical decision wisely.

Essential Qualifications

IICRC Certification: The Institute of Inspection, Cleaning and Restoration Certification is the industry’s gold standard. Look for companies with certified technicians, particularly:

- Water Damage Restoration Technician (WRT)

- Applied Structural Drying (ASD)

- Advanced Structural Drying (ASD)

Ask to see certificates and verify they’re current; certification requires ongoing education.

Insurance and Licensing: Verify:

- Comprehensive general liability insurance ($1 million+ coverage)

- Workers’ compensation insurance

- Pennsylvania contractor licensing

- Local business licenses

Industry Memberships: Affiliations with:

- Restoration Industry Association (RIA)

- Better Business Bureau with A+ rating

- Local chamber of commerce

Experience and Capabilities

Local Knowledge: Companies familiar with Roslyn’s:

- Typical construction styles and materials

- Seasonal weather challenges

- Local building codes and requirements

- Municipal inspection processes

Comprehensive Services: Full-service restoration from emergency response through reconstruction eliminates coordination headaches and ensures continuity.

Equipment Ownership: Companies owning their equipment fleet deploy immediately. Companies renting equipment create delays.

Staff Size: Adequate staffing ensures rapid response and capacity to handle your project without delays.

Response Capabilities

True 24/7 Availability: Not just answering services; actual emergency response teams available nights, weekends, holidays.

Guaranteed Response Times: Written commitments to arrive within 60-90 minutes for emergencies.

Emergency Services: Immediate availability of:

- Water extraction equipment

- Emergency board-up and tarping

- Content pack-out and storage

- Temporary power if needed

Insurance Expertise

Preferred Provider Status: Many insurance companies maintain preferred provider lists. While not required, these companies have proven track records.

Direct Billing: Ability to bill insurance directly simplifies the process, though understand what you’re agreeing to.

Documentation Excellence: Companies expert in insurance requirements provide documentation supporting claims and reducing disputes.

Claims Assistance: Helping navigate claims processes, communicate with adjusters, and resolve coverage questions.

Reputation Verification

References: Request and contact recent local references facing similar situations. Ask about:

- Response time

- Communication quality

- Work quality

- Timeline adherence

- Problem resolution

- Final satisfaction

Online Reviews: Check multiple platforms:

- Google Reviews

- Better Business Bureau

- Angie’s List / HomeAdvisor

- Facebook reviews

Look for patterns, not single reviews. Every company has occasional complaints; how they respond matters.

Awards and Recognition: Industry awards, community involvement, and recognition from trade organizations indicate commitment to excellence.

Red Flags

Avoid companies that:

- Use high-pressure sales tactics

- Won’t provide written estimates

- Lack verifiable insurance or licensing

- Can’t provide references

- Quote significantly below competitors (likely cutting corners)

- Won’t explain their processes

- Refuse to answer questions

- Ask for large upfront payments

Questions to Ask

Before hiring any company for water damage restoration in Roslyn, ask:

- Are your technicians IICRC certified? Which certifications?

- How quickly can you respond to my emergency?

- Do you own your equipment or rent it?

- Will you handle insurance communication?

- What’s included in your estimate?

- What warranties do you provide?

- Can you provide references from recent Roslyn projects?

- How do you handle unexpected issues or additional damage discovered?

- What’s your process for moisture detection and verification?

- Who will supervise my project daily?

The answers reveal professionalism, transparency, and capability. Trust your instincts; if something feels wrong, keep looking.

Making the Final Decision

Consider:

- Certifications and qualifications

- Response capabilities and availability

- Insurance expertise

- Communication quality during initial contact

- Clarity and detail of estimate

- References and reputation

- Your comfort level with the company

Don’t let emergency pressure force a poor decision. Taking an extra 30 minutes to verify credentials and compare companies can save thousands in the long run.

For additional considerations, reviewing approaches to related services like damage restoration in Royersford illustrates how professional companies approach similar challenges across different communities.

Conclusion: Protect Your Investment, Protect Your Family

Water damage strikes suddenly and without warning. But as this comprehensive guide demonstrates, successful recovery isn’t about luck; it’s about knowledge, preparedness, and professional intervention.

The nine steps outlined here; from immediate safety assessment through final verification; represent decades of industry experience refined into best practices that consistently deliver successful outcomes. Each step builds on the previous one, creating a comprehensive process that addresses not just visible damage but hidden threats that cause long-term problems.

Your Roslyn home is likely your largest investment and your family’s sanctuary. Protecting it requires both prevention and preparedness. Implement the prevention strategies discussed; inspect plumbing regularly, maintain drainage systems, winterize properly, and install early warning systems. These proactive measures prevent the majority of water damage scenarios.

But when prevention fails and water damage occurs, speed and professional expertise make all the difference. The gap between a manageable restoration costing a few thousand dollars and a disaster costing tens of thousands is often measured in hours. Companies specializing in water damage restoration in Roslyn provide the rapid response, technical expertise, and comprehensive services that transform disaster into temporary inconvenience.

The investment in professional restoration pays for itself through:

- Minimized damage through rapid intervention

- Thorough moisture detection preventing hidden problems

- Proper drying eliminating mold risk

- Complete sanitization ensuring safety

- Quality reconstruction protecting property value

- Comprehensive documentation supporting insurance claims

- Peace of mind knowing work was done right

Don’t wait for disaster to identify restoration resources. Research companies now, verify their credentials, and save emergency contact information where it’s readily accessible. If you’re currently facing water damage, don’t delay; every hour increases damage and costs.

Remember the key lessons:

- Time is critical; response within 24 hours reduces damage by up to 80%

- Hidden moisture causes long-term damage; professional detection is essential

- Proper drying prevents mold; the most common cause of restoration failure

- Documentation supports insurance claims and protects your interests

- Professional expertise saves money despite higher upfront costs than DIY

Your Roslyn home has weathered Pennsylvania’s challenging climate; it can continue to do so with proper care, maintenance, and professional intervention when water damage occurs.

For immediate emergency assistance or questions about protecting your property, professional restoration services are available 24/7 at (267) 834-5900. Don’t let water damage rob you of your investment; expert help is just a phone call away.

Connect With PuroClean

Stay informed about property protection, restoration insights, and emergency preparedness:

Follow us on social media:

Visit or contact us: 2033 Lucon Rd, Bldg. Rear, Schwenksville, PA 19473

(Available 24/7) Get Directions and Leave a Review